The Hidden Costs of Manual Purchase Order Processing in Manufacturing

Manual purchase order (PO) processing continues to be a major source of inefficiency across the manufacturing industry. With high-volume procurement cycles and tight production schedules, manufacturers relying on paper-based or semi-digital methods face delays at every step, from initial request to final approval. Errors in data entry, misplaced POs, or lagging approvals can delay raw material delivery, disrupt production timelines, and increase operational costs. These delays often cascade into inventory issues, expedited shipping costs, or idle machines, all of which eat into margins.

Additionally, manual processes provide little transparency. Procurement teams struggle to track PO statuses, monitor spending trends, or respond to supplier queries in real time. This lack of visibility makes it harder to manage cash flow, enforce compliance, or prepare for audits.

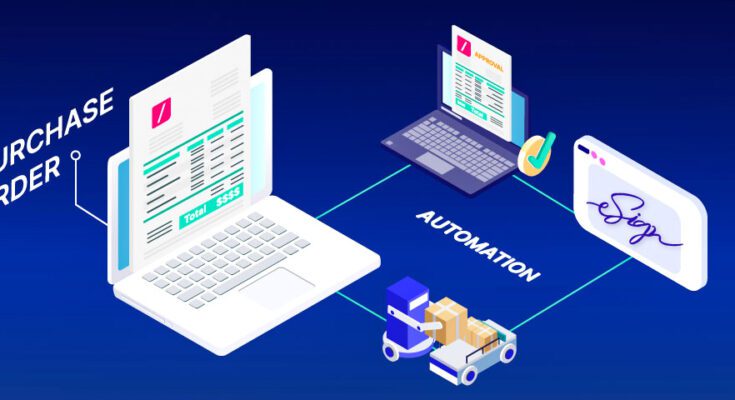

Purchase order automation, offered by solutions like OrderAction, addresses these challenges by digitizing and standardizing the entire workflow, from PO creation and approval routing to supplier communication and ERP integration. Manufacturers who implement automation gain faster cycle times, reduced error rates, and full visibility into procurement activity. In today’s competitive landscape, PO automation is not just a cost-saver, it’s a strategic advantage.

What Is Purchase Order Automation and Why It Matters for Manufacturers

In the fast-paced manufacturing industry, speed, accuracy, and timing are critical, especially when it comes to order processing. Purchase order automation refers to the use of intelligent systems to digitize and streamline the entire purchase order lifecycle, from requisition to approval, fulfillment, and archiving. For manufacturers, this isn’t just a convenience, it’s a competitive necessity.

Automated PO systems help eliminate manual data entry, reduce human errors, and ensure that the right materials are ordered at the right time. With real-time tracking and centralized document control, manufacturers gain full visibility into order status, approvals, and vendor performance. This level of transparency ensures that procurement is aligned with production timelines and inventory needs.

Key benefits of purchase order automation for manufacturers include:

• Shorter PO cycle times and faster order processing

• Improved accuracy and reduced risk of duplicate or lost orders

• Stronger supplier relationships through timely communication

• Better compliance with audit trails and approval workflows

By modernizing PO workflows, manufacturers can minimize production delays caused by missing or late materials and make smarter purchasing decisions based on actionable insights. purchase order automation turns procurement into a strategic driver of efficiency and growth.

Key Benefits of Automating Purchase Orders for Production Teams

For production teams in manufacturing, delays, stockouts, and supplier miscommunication can grind operations to a halt. Automating purchase orders streamlines procurement workflows and directly supports smoother production cycles. When purchase orders are manually created and tracked, production teams face constant risk: misaligned delivery schedules, incomplete order histories, and time-consuming approval bottlenecks.

With Purchase Order Automation in place, production teams gain:

• Real-time visibility into order status, ensuring critical materials arrive when needed

• Faster cycle times with automatic routing and approval of POs

• Stronger supplier coordination through system-triggered updates and confirmations

• Reduced inventory overhead by enabling just-in-time ordering

• Minimized disruptions from duplicate orders, missed deliveries, or manual errors

Automated systems integrate with inventory and ERP platforms, ensuring that purchase data reflects real-time production needs. Teams no longer have to rely on spreadsheets or emails to track order progress. Instead, they get automated alerts and dashboards that keep procurement aligned with manufacturing timelines.

For manufacturers aiming to increase output and reduce downtime, automating purchase orders is more than an operational upgrade, it’s a strategic advantage. It empowers production teams to focus on execution rather than chasing paperwork.

How Order Processing Automation Helps Prevent Production Delays

In manufacturing, production schedules depend on fast, error-free order fulfillment. When order processing is manual, relying on emails, spreadsheets, or paper documents, mistakes happen. Orders are misread, approvals are delayed, and fulfillment lags behind, causing costly production delays and customer dissatisfaction.

Order processing automation eliminates these weak points.

• Orders are captured automatically from multiple sources (email, EDI, PDFs), reducing manual entry

• Data is validated and routed instantly, ensuring faster approvals and fewer errors

• Integration with ERP systems ensures order information is always accurate and up to date

• Dashboards and alerts help teams track progress and prevent bottlenecks in real time

• Lead times shrink, enabling production to start sooner and stay on schedule

By automating the entire order-to-production workflow, manufacturers reduce downtime from missing or incorrect orders. Teams spend less time chasing paperwork and more time executing orders. When production receives clear, timely instructions, output rises, and so does customer satisfaction.

In today’s just-in-time manufacturing environment, automation in order processing is not just about speed. It’s about ensuring the right materials, in the right quantities, are available exactly when needed, without exception.

Choosing the Right Purchase Order Automation Solution for Your Manufacturing Workflow

Selecting the right purchase order automation solution is critical for manufacturers aiming to streamline procurement and production. It’s not just about digitizing POs, it’s about ensuring the system aligns with your unique workflow, production timelines, and existing infrastructure.

A solution tailored for manufacturing should offer:

• Seamless ERP integration – to sync PO data with systems like SAP, Microsoft Dynamics, NetSuite, or Acumatica in real time

• Scalability – to support growing order volumes without increasing operational overhead

• Custom workflow configuration – allowing alignment with multi-stage approvals, supplier categories, or inventory rules

• Supplier portal access – to improve collaboration, confirmations, and status tracking

• Analytics and reporting – for real-time visibility into spend, delays, and vendor performance

Manufacturers should also consider vendor support, implementation time, and the ability to automate related processes like invoice matching and goods receipts. A well-matched solution accelerates procurement, reduces production bottlenecks, and helps teams stay ahead of material shortages.

The right PO automation platform isn’t just a tech upgrade, it becomes a core part of a lean, responsive manufacturing workflow.